These three freezers did not meet Minnesota Health Department standards, as was made apparent by MDH stickers on them. Although the stickers indicate they can still be used, a previous health inspector told us these freezers would have to be replaced by NSF-standard freezers when they finally broke down.

|

| This MDH sticker has been there a while. |

It also meant having to scramble when the delivery trucks arrived to make sure everything got put away before it began to thaw (which, of course, wasn't a problem in winter!). Often, because Mel and Mary were busy in the cafe when the trucks pulled up, Mike had to run out and put stuff away. Mike didn't mind this much, unless we were also busy in the store.

|

| Compliant commercial freezer, probably made in the 70s. |

We knew using the old freezers was not a long-term solution. We knew it would not be long before one or more of the freezers gave out, and also knew it would not be long before a new health inspector might make their continued use an issue. But we had already invested more than we had planned getting the place up and running, and were reluctant to spend even more.

However, in the long run, buying and installing a walk-in freezer would be necessary for the cafe to continue to operate. Also, if we were ever to sell the place, the issue would have to be addressed (yes, dear readers, we will sell Emmaville some day - we're not getting any younger!).

After going on-line and learning as much as we could about walk-ins, we ordered a model that would meet our needs. Then Mike got busy prepping the ground out back for the concrete slab on which the walk-in would be placed. We were fortunate to meet Ron, a seasoned local concrete man, who laid out the site, set up forms, poured and finished the concrete in about 4 hours over 2 days.

After going on-line and learning as much as we could about walk-ins, we ordered a model that would meet our needs. Then Mike got busy prepping the ground out back for the concrete slab on which the walk-in would be placed. We were fortunate to meet Ron, a seasoned local concrete man, who laid out the site, set up forms, poured and finished the concrete in about 4 hours over 2 days. |

| Ain't it purdy? Note the little trap door to the left.* |

The walk-in arrived on a pallet, with "some assembly required". Mike scrambled to enlarge the door opening off the back room to create access (the freezer door was about 6" taller than indicated in the specs) while the guys from Central Lakes Restaurant Supply assembled the box and installed the compressor unit.

We had to wait a couple days for our favorite (and much in demand) electrician Brandon to come out and get the new unit wired. He got it fired up for us, but noticed it was cycling on and off. After a call to the manufacturer, we had to call in a refrigeration service to have a look. It turns out the new compressor/ unit had a leak. Fortunately, the manufacturer honored the warranty and picked up the repair tab.

We got it back up and running for a few days before it resumed cycling on-off. The refigeration guys wound up coming out 4 times before the problem was fixed, but again, the manufacturer took care of the bill.

|

| TA-DAH! A very boring way to spend $10k. |

____________________

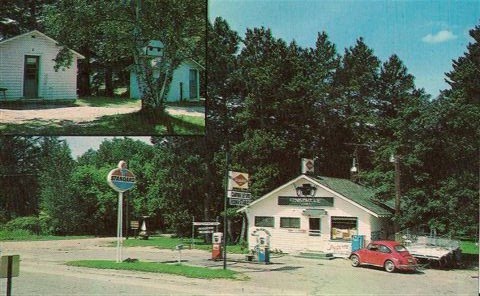

*The little trap door in the photos was used way back in the day to slide in cakes of ice. This would have been in the Lanning era (40s and 50s) before refrigeration. At that time, the trap door was part of a small shed attached to the back of the original garage. The garage, which was later used as a bait shop, was a separate building from the original store, as shown in this historic photo:

That garage is now a seating area in the cafe.